MQZ Ball Mill

MQZ Energy Saving Bearing Type Edge Drive Ball Mill, is widely used in ore dressing, chemical, coal, cement, refractory industries. The bearing type edge drive ball mill has been technology

MQZ Ball Mill -China Henan Zhengzhou Mining Machinery Co.,Ltd.

MQZ Energy Saving Bearing Type Edge Drive Ball Mill, is widely used in ore dressing, chemical, coal, cement, refractory industries. The bearing type edge drive ball mill has been technology

Ball Mill Manufacturer -China Henan Zhengzhou Mining

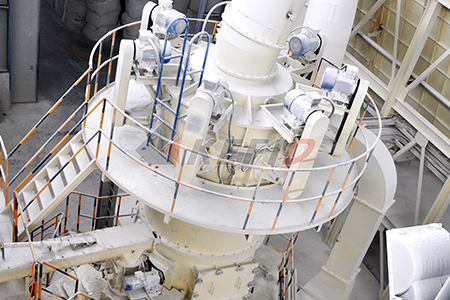

ZK Corp specializes in ball mill equipment, including wet ball mill, MQG ball mill, ceramic ball mill, mining ball mill, coal mills, ball mills with sieve, vertical mill, overflow ball mill, lab ball mill etc.

Ball Mill Jet Mill Powder Grinding Mill Impact Mill Manufacturer ...

Zhengyuan is China powder grinding mill manufacturer, offer jet mill, impact mill, ball mill, roller mill, plastic pulverizers. We also provide accessories for powder grinding equipment, like air

Ball Mill_ Rotary Kiln_Henan Zhengzhou Mining Machinery Co.,

Lime Production Line. Capacity: 50 - 1200 (tons/day) Main Material: Limestone Main Equipment: Rotary Kiln / Vertical Kiln, Cooler, Bag Filter, Preheater... Learn More.

Zhengyuan Powder Equipment

The ceramic media ball milling production line is the best solution for processing high-purity materials. It is specially designed for high-purity materials: the grinding lining and media are

立山機械工廠股份有限公司 - Lih-Shan Machinery Factory Co., Ltd.

With our ball mill and mixer, the Lih-Shan is the one which can provide main battery manufacturing process: oxide production, mixing and pasting. We are able to provide

Henan Greatwall Machinery Co., Ltd. ball mill - TradeWheel

Henan Greatwall Machinery Co., Ltd. East Factory, 600 Meters North Of The Intersection Of Taojia Road And Zhengshang Road, Zhengzhou, Henan, China, China

Ball Mill, Cement Mill, Rotary Kiln, Cement Kiln, Lime Kiln-HENAN ...

Henan Zhengzhou Mining Machinery Co., Ltd (hereinafter referred to as “Henan ZK Corp”)., founded in 1956, is a designated production unit of building materials and mining machinery

Jet Mill Ball Mill China Jet Mill Manufacturer Zhengyuan

Zhengyuan is China jet mill manufacturer. Our Jet mill, which includes cyclonic jet mill and fluidized bed jet mill, is for ultra-fine grinding of various particles, particle separating and

KARAKTERISASI MATERIAL BALL MILL PADA PROSES

material ball mill besarnya berkisar antara 80,75 – 83,58 HR A., struktur mikro yang terbentuk dari ball mill tersebut didominasi adanya karbida krom (Cr 23 C 3) yang menyebabkan meningkatnya kekerasan, kekuatan, titik lelah dan elastisitas dari ball mill tersebut dan semakin tinggi pembebanan, maka semakin tinggi ketahanan ausnya.

立山機械工廠股份有限公司 - Lih-Shan Machinery Factory Co., Ltd.

With our ball mill and mixer, the Lih-Shan is the one which can provide main battery manufacturing process: oxide production, mixing and pasting. We are able to provide customized technical solutions to reach the requirements of several kinds of battery customers.

A Comprehensive Guide to Finding the Best Ball Mill for Sale

If you’re in the market for a ball mill, you’re likely looking for a reliable and high-quality machine that can handle a wide range of materials and processes.Ball mills are used for grinding and mixing materials, and they can be found in a variety of industries, from mining and construction to pharmaceuticals and ceramics.

(PDF) Kajian Produksi Ball Mill Dalam Menentukan Efektivitas ...

2020年10月1日 Kajian Produksi Ball Mill Dalam Menentukan Efektivitas Penggerusan Bijih Timah Primer Di CV Persada Tambang Intitama TK 4.218 Paku Kabupaten Bangka Selatan. October 2020; MINERAL 5(2):1-6;

Ball Mill - SpringerLink

2024年1月1日 Ball mill is the key equipment for crushing materials after they are crushed. It is widely used in cement, silicate products, new building materials, refractories, chemical fertilizer, ferrous and nonferrous metals mineral processing, powder metallurgy, glass ceramics, and

Ball Mills in the Mineral Processing Industry - MechProTech

2024年5月27日 Ball mills’ efficiency and performance can be optimised through proper design, maintenance, and advanced technologies like MechProTech’s TITAN Ball Mill and TITAN Automatic Ball Charger. Investing in cutting-edge equipment improves operational efficiency and contributes to a more sustainable and productive future for the mineral processing industry.

Micro Ball Mill GT300 - Beijing Grinder Instrument Co.,Ltd

Micro Ball Mill GT300-Order Information: Item No. Description Please order grinding jars and balls separately: 24.890.0001: Micro Ball Mill GT300, 220V, 50/60Hz: 24.890.0003: Micro Ball Mil GT300, metal plate cover, 220V,50/60Hz Grinding jars (screw threads twisting design) Hardened Stainless steel: 01.863.0002: 5 ml: 01.863.0003: 10 ml: 01.863 ...

Proses Pengolahan Cokelat Dengan Metode Alternatif: Ball Mill –

Proses alternatif penggunaannya lebih efisien energi dan waktu. Daya yang dibutuhkan lebih kecil dan prosesnya berjalan lebih ringkas dan cepat. Saat ini sudah ada beberapa proses alternatif yang telah dikembangkan, diantaranya yaitu ball mill, melanger yang dikombinasikan dengan Stephan mixer, dan melanger yang tanpa dikombinasi.

Ball Mill Jet Mill Powder Grinding Mill Impact Mill

Zhengyuan is China powder grinding mill manufacturer, offer jet mill, impact mill, ball mill, roller mill, plastic pulverizers. We also provide accessories for powder grinding equipment, like air classifier, dust collector and rotary feeder. We offer fine grinders for different uses, such as for grinding large quantities of material, superfine grinder mills for grinding sample material and ...

(PDF) Effects of Ball Size Distribution and Mill Speed and Their ...

2020年7月2日 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a ...

The Ultimate Guide to Ball Mills - Mining-pedia

2019年8月14日 Common Types of Ball mill back to top. The common industrial ball mills mainly include cement ball mill, tubular ball mill, ultra-fine laminating mill, cone ball mill, ceramic ball mill, intermittent ball mill, overflow ball mill, grid ball mill, wind discharge ball mill, double bin ball mill, energy saving ball mill. 1.

The operating principle of the ball mill

2017年2月8日 Mill productivity also depends on other factors: number of the drum rotations, the grinding fineness, humidity and size of the crushed material, timely removal the finished product. Ball mills characterized by high energy

Laboratory Ball Mills Bench and Floor Jar Mills - Gilson Co.

Jar Mills are available in bench or floor models and have one to six jar capacities in 1, 2 or 3 tiers. They are used for wet or dry grinding, mixing and blending of ores, chemicals, ceramics, glass, and more. Benchtop Labmill is lightweight and compact and easily adjusts to four sizes of milling jars, 16-320oz (0.5–10L). Jars made of High-Density Polyethylene fit in metal reinforcing ...

A Comprehensive Guide to Ball Mill Manual

A ball mill is a crucial piece of machinery used in grinding and mixing materials in various industries. It works by rotating a cylinder with steel or ceramic balls, causing the balls to fall back into the cylinder and onto the material to be ground.

Mechanical Alloying with Ball Mills Retsch

The Planetary Ball Mill PM 300, with its large sun wheel and a maximum speed of 800 rpm, delivers a very high energy input, resulting in g-forces up to 64.4 g. With two grinding stations, the mill can simultaneously use up to four grinding jars ranging from 12-80 ml for trials.

Ball Mill Critical Speed - 911Metallurgist

2015年6月20日 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula. The mill speed is typically defined as the percent of the

Small Ball Mills - 911Metallurgist

2016年5月26日 The larger mills are custom built according to your requirements. Whatever these are there is a C. I. W. Ball Mill built to meet your particular problem at the right price. Ball Mill Capacity Table. Small Muleback BALL MILL. Small (Muleback Type) Ball Mill is built for “muleback” transportation in 30″ and 3′ diameters (inside liners).

Ball Mill Manufacturer -China Henan Zhengzhou Mining

Ball mill is mainly used for grinding in mining (metallic minerals and non-metallic minerals), cement, refractories, chemical, power plant, aluminum, building material, glass, ceramic, steel slag and fly ash, ect.It follows more crushing and less grinding principle to save energy. The feed size to ball mill shall be smaller than 25mm, the output size can be adjusted by revising steel

Ball Mills in the Mineral Processing Industry - MechProTech

2024年5月27日 Ball mills’ efficiency and performance can be optimised through proper design, maintenance, and advanced technologies like MechProTech’s TITAN Ball Mill and TITAN Automatic Ball Charger. Investing in cutting-edge equipment improves operational efficiency and contributes to a more sustainable and productive future for the mineral processing industry.